Simulation and optimization of paperboard and corrugated board

Predict the behavior of your packages or converting processes. Speed-up product development and optimize your products. The PaperFEM-suite is material models developed to accurately predict paper materials.

Simulations

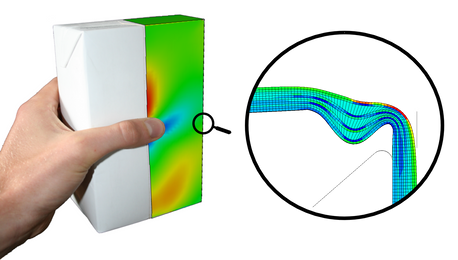

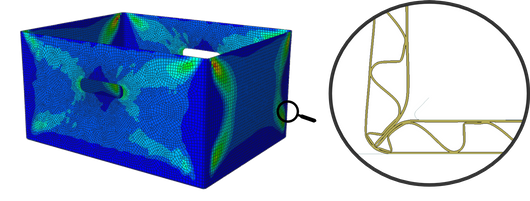

Perform detailed simulations of converting processes or simulate packages and

- create understanding of product behavior

- visualize where and to what extent the material is affected

- predict performance of different materials, product designs, manufacturing tools, etc.

Below you can see a video of a drop-test of a package filled with liquid. The other video show creep simulation of a corrugated board edge, where the force is constant and simulated over time, with this you get accurate prediction in minutes which would take months in physical tests.

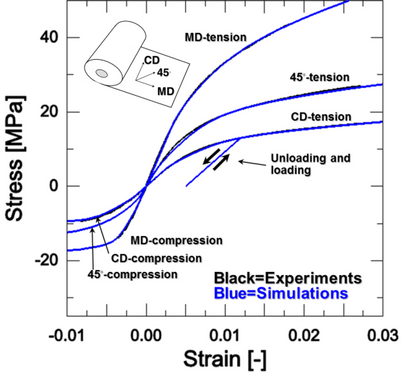

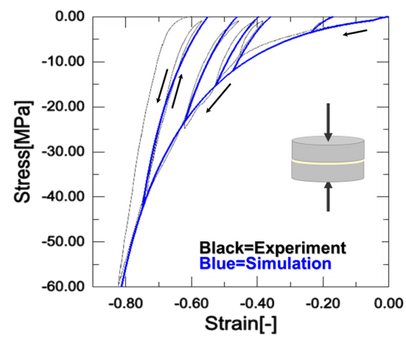

Accuracy

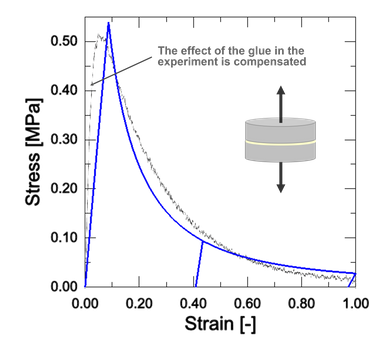

The accuracy the constitutive models are often crucial for the reliability of the simulations. The accuracy of the PaperFEM material models have been proved in many projects.

Below show in-plane and out-of-plane behavior compared to test for paperboard.

Optimization

Optimization is a

- systematic way of finding the best design

- provides support for active design decisions

- reduces material cost, design time and uncertainties

Below you can see two optimizations.

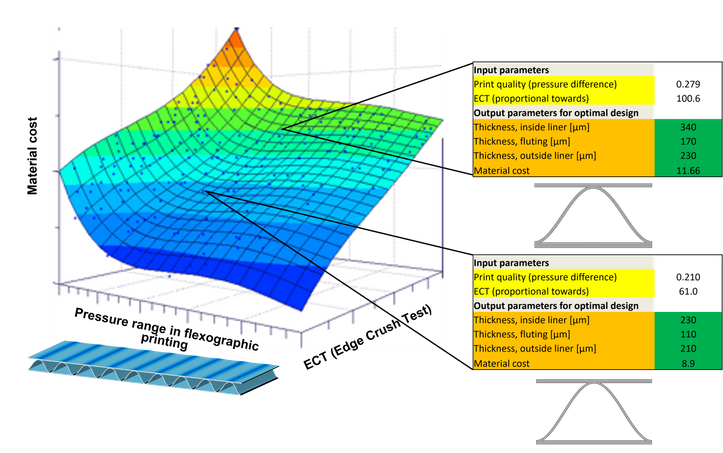

Optimization of corrugated board

This aims to find best use of the material in the corrugated board in order to decrease cost, increase stackability and reduce washboarding in flexographic printing. Each blue dot represent one design (and the two simulations). The surface is the Pareto front, i.e. only the best designs given the objectives.

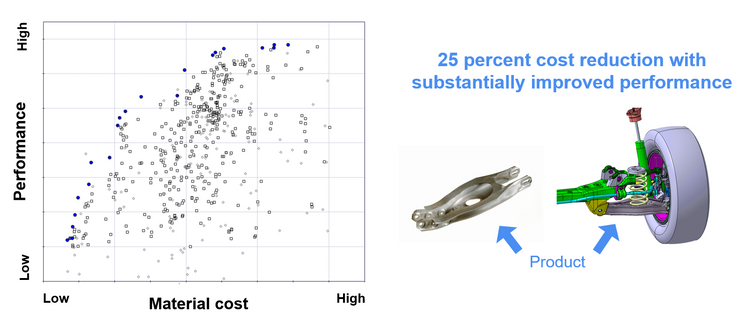

Optimization of spring seat

This optimization towards the Automotive industry aim to reduce cost and increse performance. You can read full article here

Projects

Most of the simulations om this site are pretty old. Most new development are performed in projects with costumers, one such that is communicated is the PackSimulator developed with Stora Enso.

Read more here: PackSimulator on LinkedIn

Contact

I – Tomas Andersson, creator of this site and software – am employed as group manager of Structural Mechanics at AFRY – the worlds largest consultancy firm within Pulp & Paper, and the largest consultancy firm within CAE (Computer Aided Engineering) in the Nordic countries.

Main interest are Simulation, Constitutive modeling, Optimization and new technologies for the Automotive, Packaging and Defence industries.

Link to LinkedIn-page

Contact Form